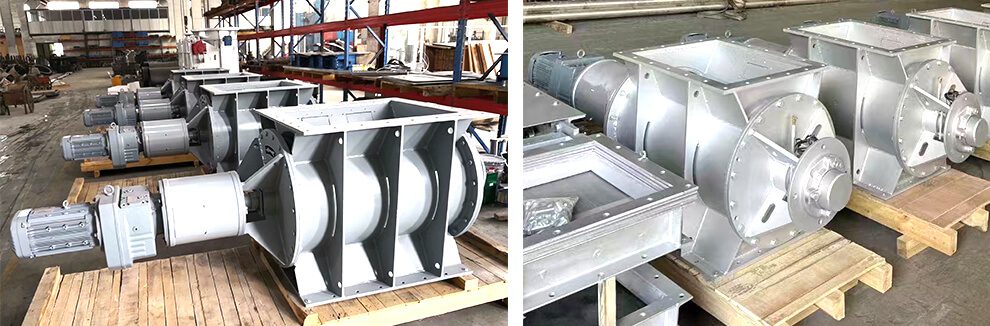

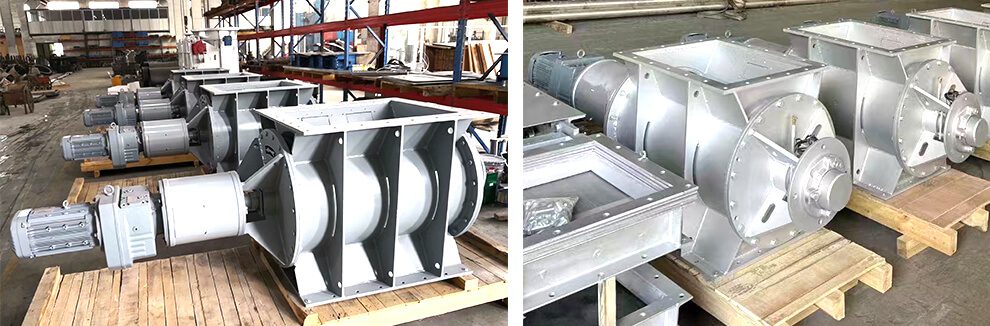

The star discharge valve is an unloading device designed for discharge points that operate under negative pressure. It conveys materials using a rotating rotor. This design provides a sealing effect that prevents air from being drawn in during pneumatic conveying, ensuring normal discharge.

Star discharge valves are commonly used in pneumatic conveying systems. They supply materials uniformly and continuously to the conveying pipe. This ensures stability for gases and solids within the pneumatic transport system. Additionally, they isolate pressure in the valve's upper and lower sections, achieving a locking effect. Therefore, the star discharge valve is essential for pneumatic conveying systems.

Star discharge valves serve as unloading devices in material collection systems, particularly for silos. They rank among the most advanced unloading devices available today. These valves are commonly used in dust removal systems and are especially suitable for dust and small particle materials. Industries such as environmental protection, metallurgy, chemicals, food, cement, road construction, and drying equipment favor star discharge valves for various projects.

Choosing the right star discharge valve involves several key steps:

Determine if the valve will be used indoors or outdoors. This choice influences protective measures.

Clarify if the valve will discharge materials in a metered, full-volume, or air-locking manner. This helps select the appropriate model.

Understand the valve's hourly flow rate. Specify whether the discharge is metered or variable to select the right capacity.